EVA Roll Film

EVA Roll Film

Product Features:

Get Free Samples

COME VISIT US AT OUR HQ.

Our headquarters are based in shandong Province China.

Details

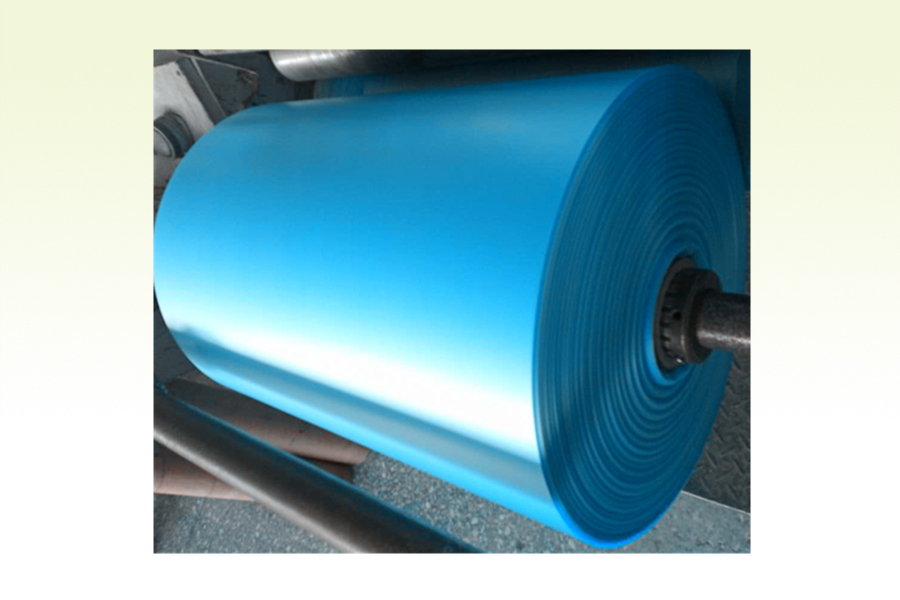

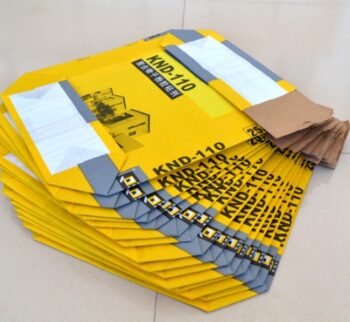

EVA low melting point rubber feeding bag is a patent product of our company. It was developed in 1998 and put into market in 2000. It is composed of a variety of plastic resins and various additives. It has the characteristics of low melting point and co-melting with rubber. It can be used as an effective component of rubber products. Our company can produce products with melting point of 70℃–115℃, adjust the degree of melting point according to user’s requirements, and can also make bags of various colors, sizes and thicknesses. The bags can be processed by anti-skid embossing, printing and so on. The bag can also be perforated to facilitate the discharge of gas in the bag during filling. The product has high tensile strength, impact strength, puncture resistance, softness and elasticity like high quality rubber. Such bags are mainly used for packing rubber series products and various chemical raw materials, and can be put into rubber refining equipment with raw materials, and can melt with rubber without affecting the quality of rubber products. To use “low melting point rubber feeding bag” to pack all kinds of raw materials can eliminate the dust flying, reduce environmental pollution, and decrease the potential hazards of harmful substances to workers. According to the shape of the bags, they can be divided into: Features √A: EVA Low Melting Point Valve Bag EVA low melting point valve bag is currently the international popular packaging bag. It is fed from the valve top, which is convenient for filling materials, and the sealing is simple and easy, which reduces the filling cost and improves the filling efficiency. After filling the material, the bag is in cubic shape. Valve bags are the most suitable packaging solution for enterprises with automatic filling machines. Customers can directly put the packaged products into the refining furnace, and the packaging bags will be melted together with rubber without affecting the quality of rubber products. √B: EVA Low Melting Point Open-End Bag By using the EVA low melting point open-end bag, users can conveniently directly pack the resin or additives into the bag. The melting point can be adjusted according to the user’s requirements, and various colors, sizes and thicknesses can also be adjusted. The bag can be processed by anti-skid embossing, printing and so on. The bag can also be perforated to facilitate the discharge of gas in the bag during filling. The product has high tensile strength, impact strength, puncture resistance, softness and elasticity like high quality rubber. √C: EVA Low Melting Point Vest-shaped Bag EVA low melting point vest-shaped bag is the rubber feeding bag with special shape. The melting point can be adjusted according to the user’s requirements, and various colors, sizes and thicknesses can also be adjusted. The bag can be processed by anti-skid embossing, printing and so on. √ D: EVA Low Melting Point Color Film EVA low melting point color film, which exists in the form of roll film, can be used to package solid rubber additives for rubber refining. The melting point can be adjusted according to the user’s requirements, and various colors, sizes and thicknesses can also be adjusted. The bag can be processed by anti-skid embossing, printing and so on.