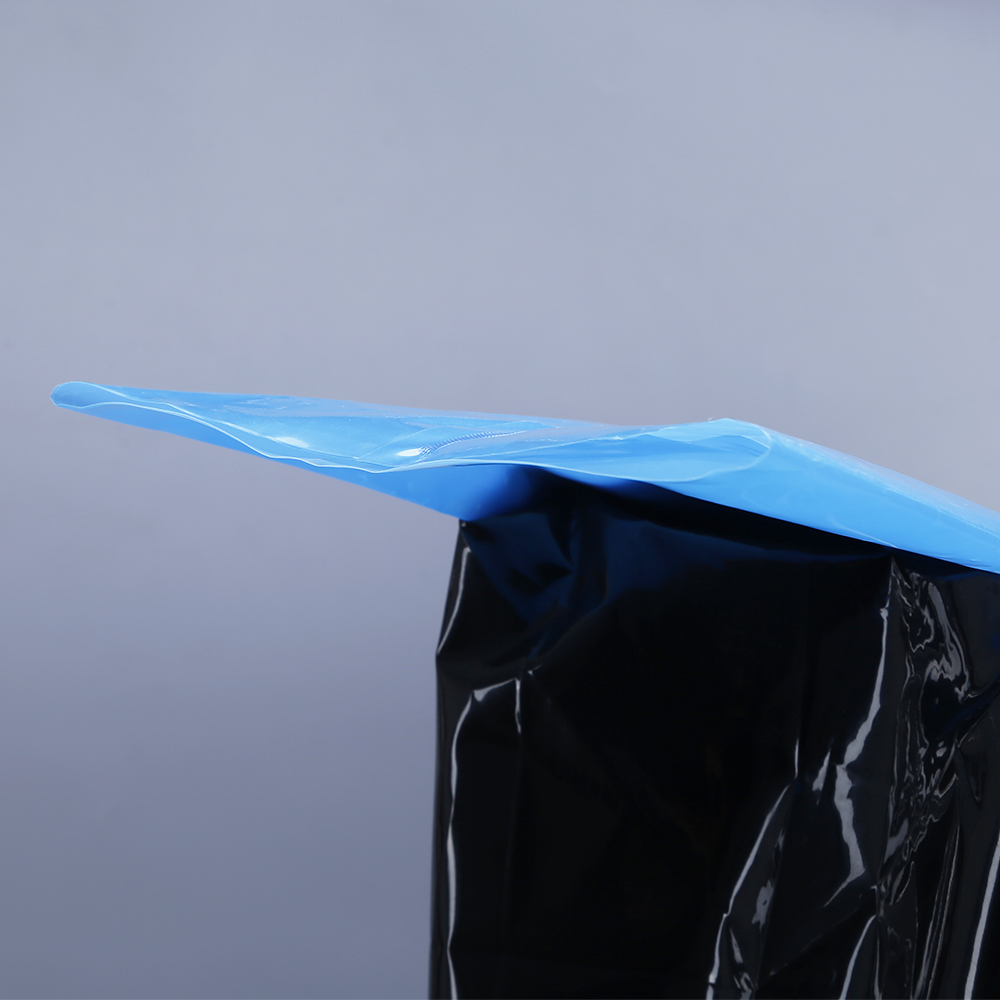

LDPE valve bag

LDPE valve bag

Product Features:

This kind of packing bags has the advantages of good transparency, strong self-stickiness, easy operation and high tensile strength. Using this kind of bags, it can save the packing time, space and production cost. At present, the commonly used models on the market are square bottom valve bags, square bottom open-end bags and open-end heat-sealing bags. According to the user’s needs, we can produce bags of various colors, sizes and thicknesses, and the bags can be processed by anti-skid embossing, printing and so on. The bag can also be perforated to facilitate the discharge of gas in the bag during filling. It is widely used for packing in chemical industry, plastic raw materials, building materials and other industries. Our company can produce various PE bags according to user’s needs, such as PE valve bags, PE open-end bags, color PE bags, low melting point PE bags, anti-skid PE bags, anti-static PE bags, etc.

Get Free Samples

COME VISIT US AT OUR HQ.

Our headquarters are based in shandong Province China.

Details

√A: PE Square Bottom Valve Bag PE square bottom valve bag is fed from valve top, which is convenient for filling material, and the sealing is simple and easy, which reduces the filling cost and improves the filling efficiency. After being filled with material, the bag is in cubic shape. The valve bags are the most suitable packaging solution for enterprises with automatic filling machines. The bag surface can be processed by anti-skid embossing. It is suitable for stacking transportation, and the stacking is neat and beautiful, which is easy to be handled and transported. It has high strength and low breakage rate, which greatly improves the reputation of the product. √B: PE Square Bottom Open-end Bag PE square bottom open-end bags, also known as open-end and pasted bottom bags, are prevalent in the food and additive industries in foreign enterprises. Domestic foreign-funded enterprises and export enterprises have begun to adopt such bags in succession. PE square bottom open-end bags are filled by traditional filling machines. After filling, the upper part can be sewn with thread, and the stacking of such bags is neat and beautiful. The full-paper open-end square bottom bags are environment-friendly packaging bag products. They are suitable for packaging dyes material, starch, flour, food additives, plastics, chemical products, carbon black and so on.

Related Products